Energy master plan for NKT, Cologne

Climate-neutral heating and cooling supply concept for an industrial production with efficient waste heat usage

How can an energy-intensive industrial site become climate-neutral without losing economic viability and supply security? For NKT Cologne, we developed an energy master plan that intelligently combines waste heat utilisation, electrification, and renewable energies. The result: an innovative transformation pathway showing how carbon emission reduction and industrial efficiency can be combined.

The production facility of NKT GmbH Co. KG in Cologne is one of the company's most energy–intensive sites, with high demands for heating, cooling, and process energy. At the site, AC and DC high-voltage cables are manufactured - essential components for the energy transition. Particularly the DC high-voltage cables play a key role in Germany's future electricity infrastructure. NKT's cables are used, among other things, for the realisation of the major power corridors SuedOstLink and SuedLink, connecting renewable energy production with energy-intensive regions. Without these cables, the energy transition cannot be realised.

Challenge: Carbon emission reduction in energy-intensive production facilities

To reduce carbon emissions at the production site by 2030 and to make the energy supply more sustainable in the long term, the development of an energy master plan was necessary. The goal was to identify potentials for waste heat utilisation, electrification, and integration of renewable energies, and to develop economically viable solutions. The focus was not only on reducing emissions but also on ensuring a reliable and economically efficient energy supply system.

Detailed analysis as the basis for efficiency increase

The interdisciplinary planning team of MorgenGrün conducted a detailed analysis of the energy flows at the site. This included a comprehensive demand analysis with hourly waste heat profiles based on the production process, an evaluation of renewable energy sources, and a simulation of various scenarios for the optimal supply security. The existing infrastructure was reviewed for efficiency to best utilise synergies between different energy sources and to exploit unused potentials.

Innovative measures for sustainable energy supply

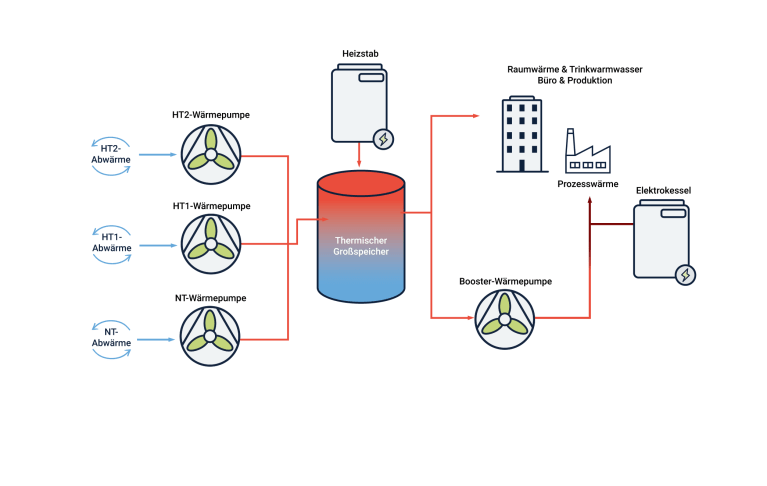

- Waste heat utilisation: Three waste heat heat pumps at different temperature levels exploit previously unused heat sources from industrial cooling circuits and store this energy in a central industrial hot water storage. The use of this waste heat significantly reduces the need for fossil fuels and increases the overall efficiency of the energy supply.

- Electrification of process heat: Heat from the thermal storage is used to heat production and office buildings. Additionally, a booster heat pump uses the heat from the storage to provide process heat at a temperature of 85°C. Electric boilers cover peak heat demands.

- Photovoltaic integration: The installation of photovoltaic systems on the large roof areas of the production facility could ideally complement the electrified heat supply in a future second expansion phase, as the required electricity can be generated on-site. This could contribute to the sustainable power supply of the site and reduce the draw from the public grid.

- Optimisation of heat transfer: The conversion from gas-based radiant heaters in the production hall to water-based heating systems enables a significant reduction in the required supply temperatures. An analysis also showed that the office building is already suitable for low-temperature operation. This increases the efficiency of the overall system, especially the heat pumps.

- Intelligent control and monitoring: By implementing a digital energy management system, all energy flows can be monitored and verified in real time. This enables demand-oriented control of heating and cooling supply as well as continuous efficiency improvement.

Result: A significant step towards climate neutrality

With the developed master plan, the carbon emissions of the Cologne production facility can be drastically reduced, and the use of natural gas can be completely replaced. By consistently utilising existing energy sources and targeted electrification, not only can operating costs be significantly reduced, but long-term supply security can also be ensured. The measures have been summarised in a prioritised roadmap and will be implemented step by step to ensure a sustainable transformation of the site.

Future perspectives: Model for sustainable industry

The energy master plan presented by MorgenGrün lays the foundation for fully climate-neutral production at NKT Cologne. Through the clever combination of waste heat utilisation, electrification, and renewable energies, not only is the environmental impact minimised, but the competitiveness of the company is also strengthened. The concept can serve as a model for other industrial sites and shows how innovative technologies and intelligent planning make industrial production fit for the future.

Conclusion: Energy efficiency as a competitive advantage

The energy master plan for NKT Cologne is a groundbreaking example of sustainable industrial energy supply. It shows how strategic planning and modern technologies successfully implement energy efficiency and decarbonisation on an industrial scale. Through the successful combination of waste heat utilisation, electrification, and renewable energies, a resilient and economically viable transformation pathway towards climate neutrality is created.

Project Start and Implementation

Since March 2025, ZWP Ingenieur-AG and MorgenGrün have been working together on the concrete planning and implementation of the concept. A central challenge is to integrate the new heat supply structure into ongoing operations in such a way that production can continue without interruption. Close coordination with the operations team and step-by-step implementation are the focus.

Images: © MorgenGrün

Overview

Client

NKT GmbH & Co. KG, Cologne

Time frame

2024

Services

Energy master plan for decarbonisation and preparation for subsequent planning and implementation by ZWP Ingenieur-AG

Gross floor area (GFA)

approx. 40.000 m²

Saved CO2 emission

1.215 t/a