Combined pumping station at the large sewage treatment plant in Cologne-Stammheim

Sustainability and innovative planning for resource-saving solutions in plant construction

The new construction project for the combined pumping station at the large sewage treatment plant in Cologne-Stammheim focuses on innovative solutions in the area of resource conservation and sustainability. Particular attention was paid to the planning of the machine room, the shell of which is largely made of wood.

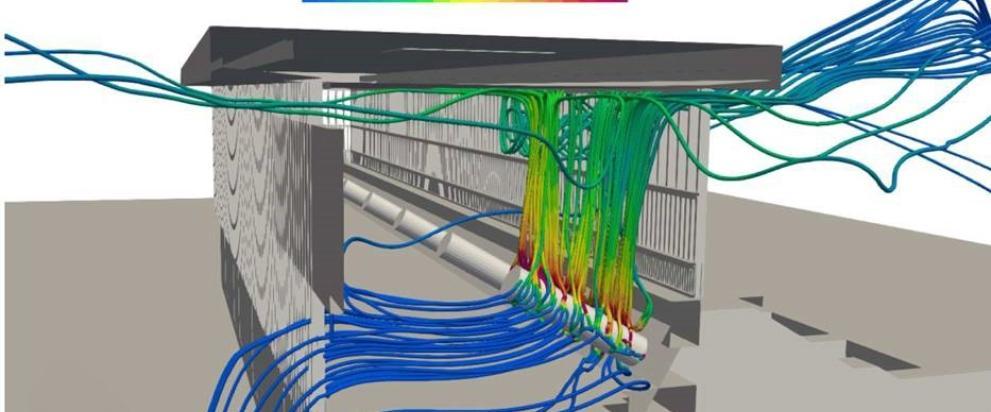

This sustainable approach is also reflected in the overall building design, which emphasises the choice of environmentally friendly materials as well as the energy efficiency of the building. A key challenge was the temperature control of the pump house, particularly with regard to the waste heat from the pumps. The original plan envisaged the use of a mechanical ventilation system to dissipate the heat generated. However, with the help of flow simulations, we were able to prove that the heat could be sufficiently extracted through the wooden slits in the façade, which meant that the internal temperature was only around four to five degrees above the external temperature. This meant that an expensive and energy-intensive ventilation system could be dispensed with, which not only saved costs but also contributed to a reduction in energy consumption.

Temperature control in electronics and storage rooms

Another issue was temperature control in the neighbouring electronics and storage rooms. As condensation had to be avoided due to the sensitive electronics, additional insulation of the rooms was considered. However, our thermal simulations showed that the formation of condensation would only be a problem for a few hours of the year. Instead of costly insulation, we recommended controlling the heating specifically according to the dew point temperature. This solution minimises the additional energy requirement and avoids unnecessary investment.

Optimisation through simulations

Our services, which included thermal and flow simulations, made a significant contribution to optimising the project in terms of both energy and ecology. Thanks to the targeted avoidance of inefficient systems and the use of sustainable solutions, the new construction project at the large sewage treatment plant in Cologne-Stammheim is not only convincing in economic terms, but also in terms of resource conservation and energy efficiency.

Images: © Stadtentwässerungsbetriebe Köln

Overview

Client

Large sewage treatment plant Cologne-Stammheim

Time frame

2023 to 2024

Services

Thermal simulation, flow simulation

Gross floor area (GFA)

250 m²